Mould Manufacturing

Tool making at Sargodha is an area of real expertise, offering all clients a fully equipped in-house tool room enabling a wide variety of mould tools to be produced from simplistic open and shut tooling, to the highest technically designed tools.

Tools are made, modified and maintained within Sargodha without the need to outsource. Tool making is also offered to other plastic moulding businesses who do not have the luxury of an inhouse resource. CAD/CAM software is utilised to read 3D models and if required we can produce a rapid prototype which once approved the data can be used to produce tool parts. The team of Sargodha tool makers then manufacture precision tools using the finest steels and many years of experience. we have established a strong reputation for quality and are today one of the leading in house toolmakers in india

Sargodha have all of the facilities necessary to design and manufacture mould tools from start to finish under one roof. Equipment includes latest CAD/CAM, moldflow, milling, high speed milling, grinding, turning,cnc machining centres and spark nerosion machines Designing and Manufacturing mould tools for the Automotive, Medical and Electrical Industries, working to customer specific requirements and tight tolerances, has given Sargodha vast experience in understanding what goes into a winning design.Whilst remaining competitive on both costs and lead times, Sargodha will always ensure that all tooling manufactured will be of the highest quality, utilising best design practices, quality materials and the most appropriate manufacturing methods.

If a lifetime lasting tool is not required then prototype or soft tools can be produced. The tools can be manufactured to your budget we even have partners if chinese tooling is required and we can project manage these tools

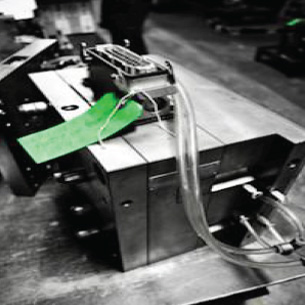

Our State of Art Mould Making Tool Shop

An Array of Moulds Developed For House Hold, Automobile, Appliances & Electronics Sector

Wide Range Of Moulds Developed In House & From Our Tieup in China

Sargodha can take your project from preliminary design through detailed design & mold construction to initial product sampling, and finally full-scale production. Our primary focus is the customer. We are driven by an unsurpassed commitment to quality and a passion for excellence.

We seek to form a partnership with our customers whereby we work together to develop custom and unique solutions to the most challenging projects.